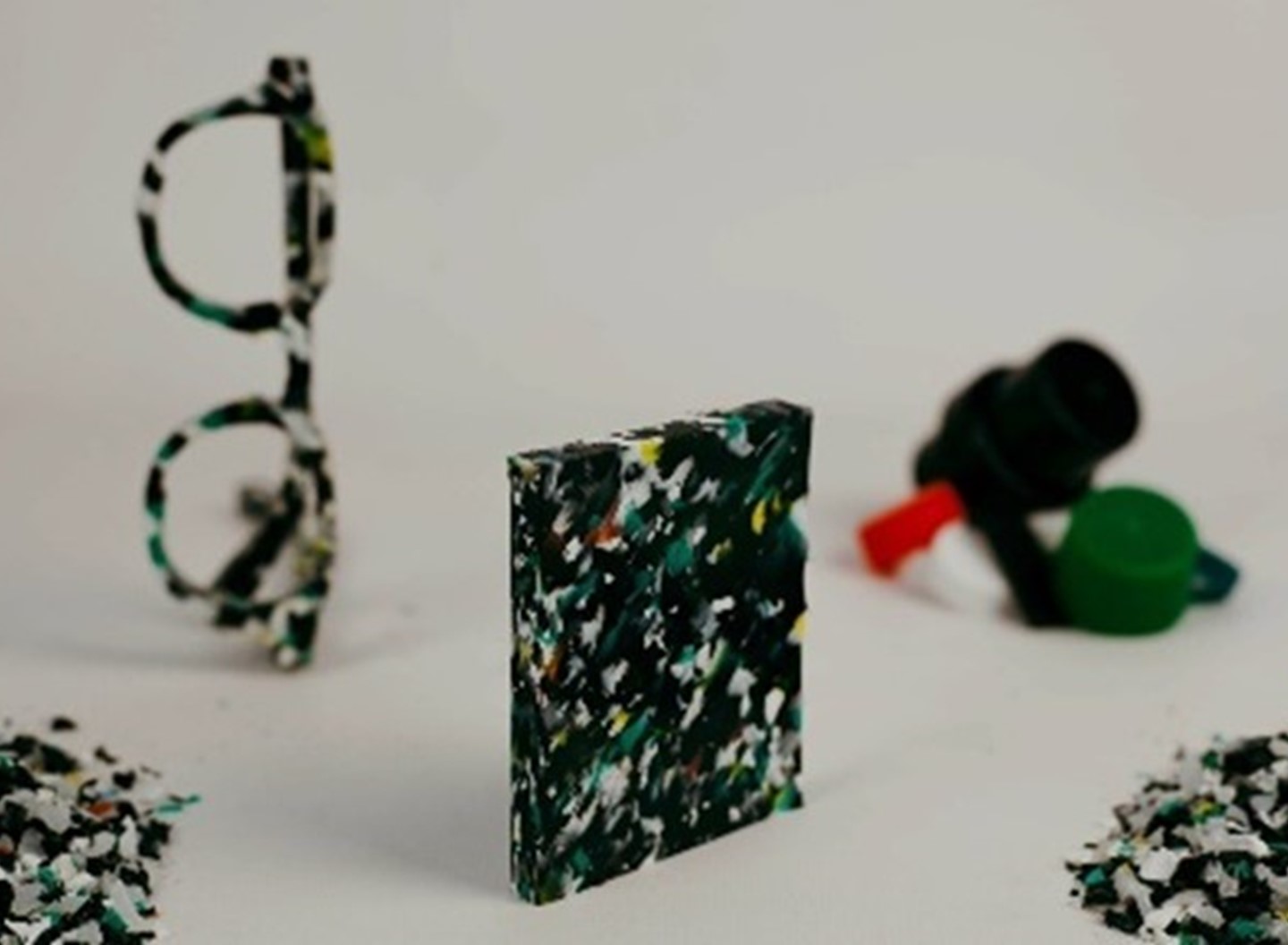

NEW PRODUCT / SOLUTION

Recycled plastic panels

APPLICATION SECTOR

Rigid plastic

VALORIZED OUTPUT

Packaging scraps

TRL

Deploy

CONTEXT

Global

SDG

VALUE CHAIN AREA

Reprocessing packaging scraps into plastic bars can provide both environmental and economic advantages over using virgin plastic resin, particularly when supported by an efficient and well-established collection and processing infrastructure.

Additionally, incorporating recycled materials like packaging scraps into plastic bar production can help companies comply with regulatory requirements and achieve sustainability goals related to waste management and recycling.

Source:

- ICO 2024, Beyond Coffee: Towards a Circular Coffee Economy coffee-development-report-2022-23.pdf

DESCRIPTION

IMPACTS

Packaging scraps often contain a mix of plastic types, requiring advanced sorting technologies to ensure uniformity in the final plastic bars. Additionally, during recycling, plastics can degrade due to heat, mechanical stress, and chemical reactions, leading to reduced mechanical strength and increased brittleness.

Furthermore, ensuring compliance with regulations and standards for recycled plastics—covering safety, quality, and environmental requirements—is essential for their successful use in manufacturing.

CHALLENGES AND LIMITS

EXAMPLES OF APPLICATION

Italian based startup committed to the plastic reabsorption through the recycling and valorisation of spent plastic for new projects with new visual patterns and different densities.